In January 2025, France Hydrogène counted 80 hydrogen refueling stations in France with a further 91 stations considered to be under construction or planned.

One of the largest installed bases in Europe

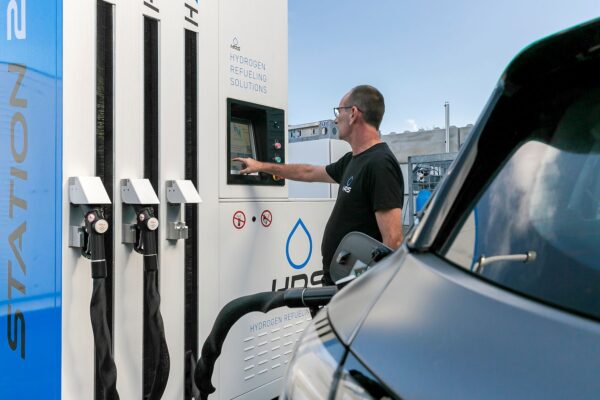

Between 2009 and 2019, HRS produced 34 stations for a major client. These were installed in Germany, France, Denmark, and the USA.

Following a change in the company's strategy to include the design and installation of new-generation stations, HRS has installed 28 stations between 2020 and 2024 in France, the UK, Spain, Portugal, Germany and Saudi Arabia.